Description

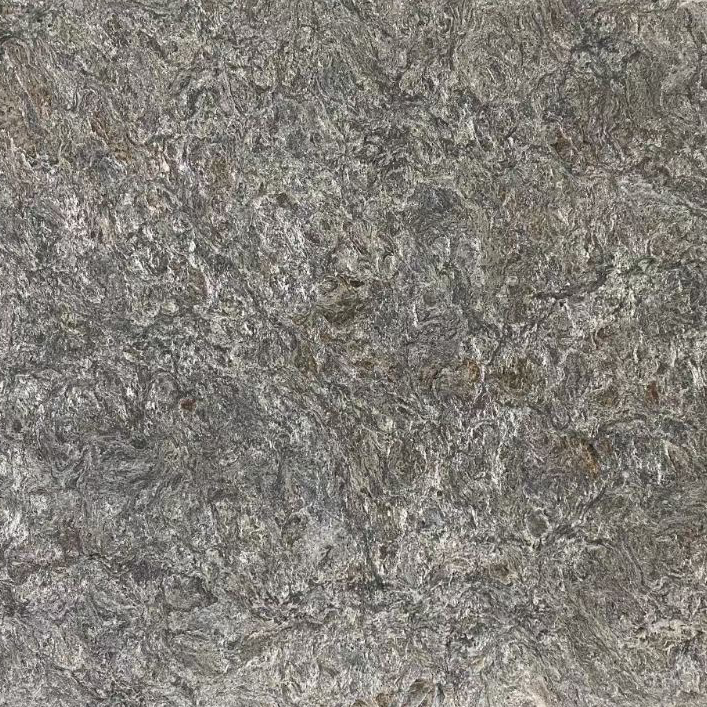

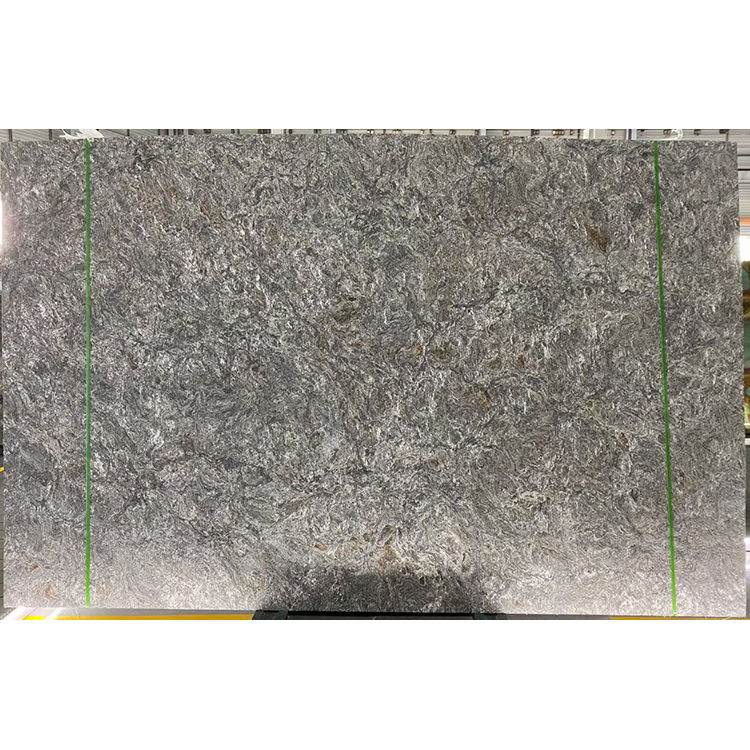

| Product Name | Slabs platinum diamond dark brown granite quartzite for wall floor tiles |

| Colors | Dark brown |

| Size | 1800(up) x 600(up)mm 2400(up) x 1200(up)mm 2800(up) x 1500(up)mm etc |

| 305 x 305mm or 12” x 12” 400 x 400mm or 16” x 16” 457 x 457mm or 18” x 18” 600 x 600mm or 24” x 24” etc |

|

| Countertops, Vanity Tops Based on Customer's Drawings | |

| Thickness | 10mm,12mm,15mm,18mm, 30mm, etc |

| Packing | Strong Standard Export Packing |

| Delivery Time | Approx. 1-3 Weeks per Container |

| Application | Countertops, Bathroom Vanity Tops, Feature wall, etc... |

Platinum diamond dark brown quartzite granite structure dense, hard texture, acid and alkali resistance, good weather resistance, can be used in the outdoor for a long time, generally used for the ground, wall, base, step, more used for outdoor wall, ground, cooking surface decoration. We are dealing with all kinds of natural granite, marble, quartzite, sandstone, limestone etc. Please contact us for more stone information.

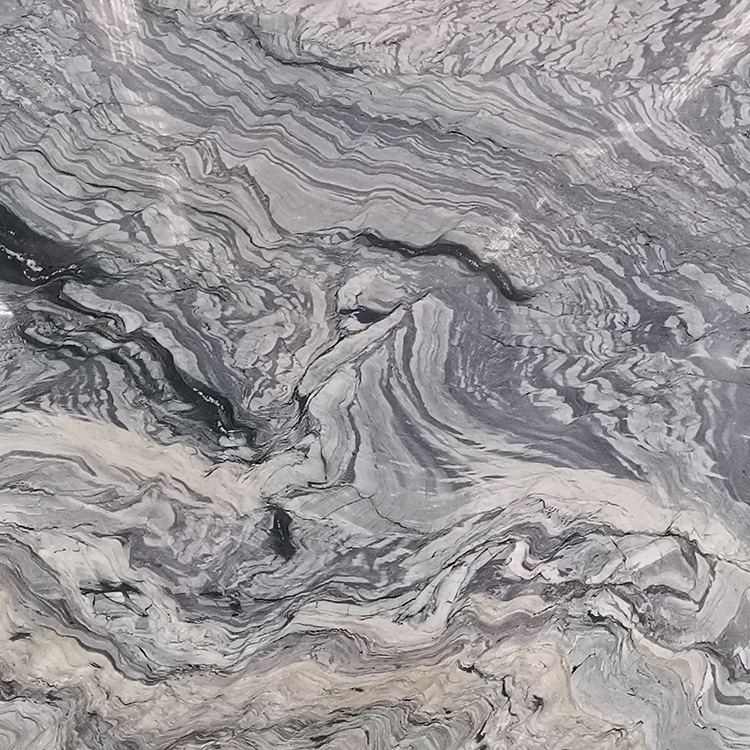

Luxury stone for home decoration ideas

Company Profile

Rising Source Group is as a direct manufacturer and supplier of natural marble, granite, onyx, agate, quartzite, travertine, slate, artificial stone, and other natural stone materials. Quarry, Factory, Sales, Designs and Installation are among the Group's departments. The Group was founded in 2002 and now owns five quarries in China. Our factory has a variety of automation equipment, such as cut blocks, slabs, tiles, waterjet, stairs, counter tops, table tops, columns, skirting, fountains, statues, mosaic tiles, and so on, and it employs over 200 skilled workers can produce at least 1.5 million square meters of tile per year.

Packing & Delivery

Marble tiles are packed directly in wooden crates, with safe support to protect the surface& edges, as well as to prevent rain and dust.

Slabs are packed in strong wooden bundles.

Carefully packing details: Each tile is covered with corner protect to avoid damage by sharp cutting of cardboard. The top of each tile is covered with protective film, which help prevent it from pressure b elated during transportation. Our hard work definitely worth your trust!

Certifications

Many of our stone products have been tested and certified by SGS to assure good quality products and best service.

About SGS Certification

SGS is the world’s leading inspection, verification, testing and certification company. We are recognized as the global benchmark for quality and integrity.

Testing: SGS maintains a global network of testing facilities, staffed by knowledgeable and experienced personnel, enabling you to reduce risks, shorten time to market and test the quality, safety and performance of your products against relevant health, safety and regulatory standards.

FAQ

What's your advantage?

Honest company at a reasonable price with competent export service.

How can you guarantee quality?

Before mass production, there is always a pre-production sample; Before shipment, there is always a final inspection.

Whether do you have a stable stone Raw materials supply?

A long term cooperation relationship is kept with eligible suppliers of raw materials, which ensures the high quality of our products from 1st step.

How is your quality control?

Our quality control steps include:

(1) Confirm everything with our client before moving to sourcing and production;

(2) check all the materials to ensure they are correct;

(3) Employ experienced workers and give them proper training;

(4) Inspection throughout the whole production process;

(5) Final inspection before loading.

Welcome to inquiry and visit our website for more product information

-

Best price brazil blue azul macauba quartzite f...

-

Blue fusion quartzite countertops for custom ki...

-

Prefab blue lava quartzite stone slabs for coun...

-

Natural stone slabs blue roma quartzite for kit...

-

Brazil natural roma blue imperiale quartzite fo...

-

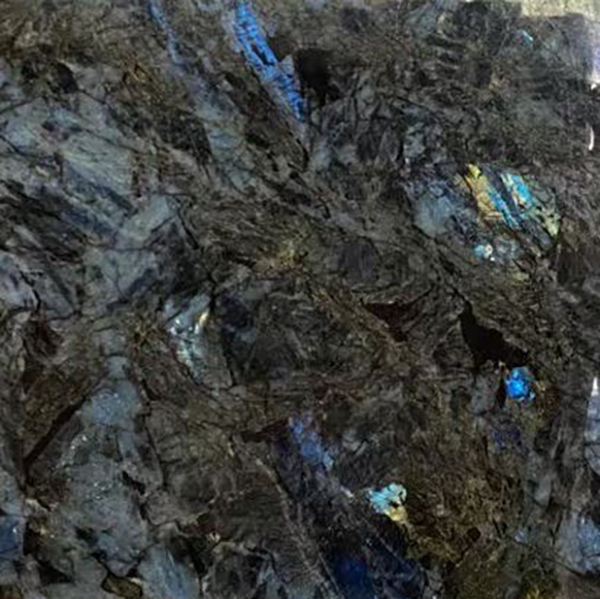

Luxury stone labradorite lemurian blue granite ...